It’s been a while, but we’re back with some more tech. Today we’re taking a look at connecting Water Temperature and Oil Pressure gauges to a Ford 4.6L Modular Motor. These points will be helpful whether you’re working on an original equipment engine or on a swap application. We’re going to start off with some tips for Coolant or Water Temperature and then move on to Oil Pressure. Now let’s get to the details…

Water Temp

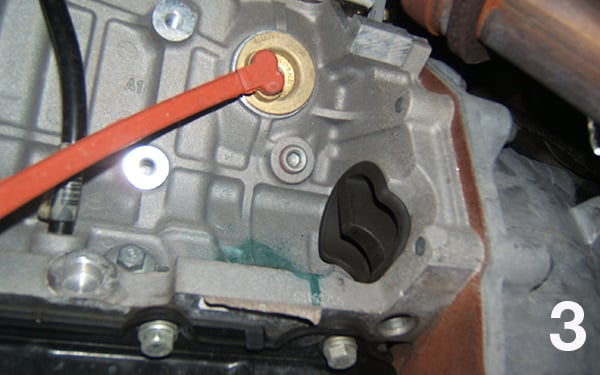

A convenient water temp port can be found on these engines on the left (driver’s) side of the engine block, below the last freeze plug. If the engine is installed while you’re performing this installation, you’ll need to most likely locate this from underneath the vehicle. This port will be one of two different sizes. Either 16mm x 1.5 or 3/8” NPT.

REMEMBER to let the engine cool completely, wear eye protection, and be ready with a catch pan as removal of this plug will result in a geyser of coolant.

It has been rumored that some of the earliest modular motors may not have this port, from around ’92 to ’95. In our current experience everything ’96 and later has this port. To identify which size your port is, simply look at the plug that is threaded into the hole. If it uses an Allen wrench (inverted hex) to remove, then this is going to be a 3/8” NPT. All of our electric gauges come with this adapter.

If you have a plug that uses a regular box-end wrench, or socket to remove (external hex), then this will be a metric, 16mm x 1.5 thread. The metric adapter number for our electric gauges is AutoMeter model #2268. Note: We do not recommend mechanical temperature gauges for this installation due to shallow coolant passage depth (mechanical probe may bottom out resulting in damage to the gauge or improper sealing).

Oil Pressure

There are a few options here.

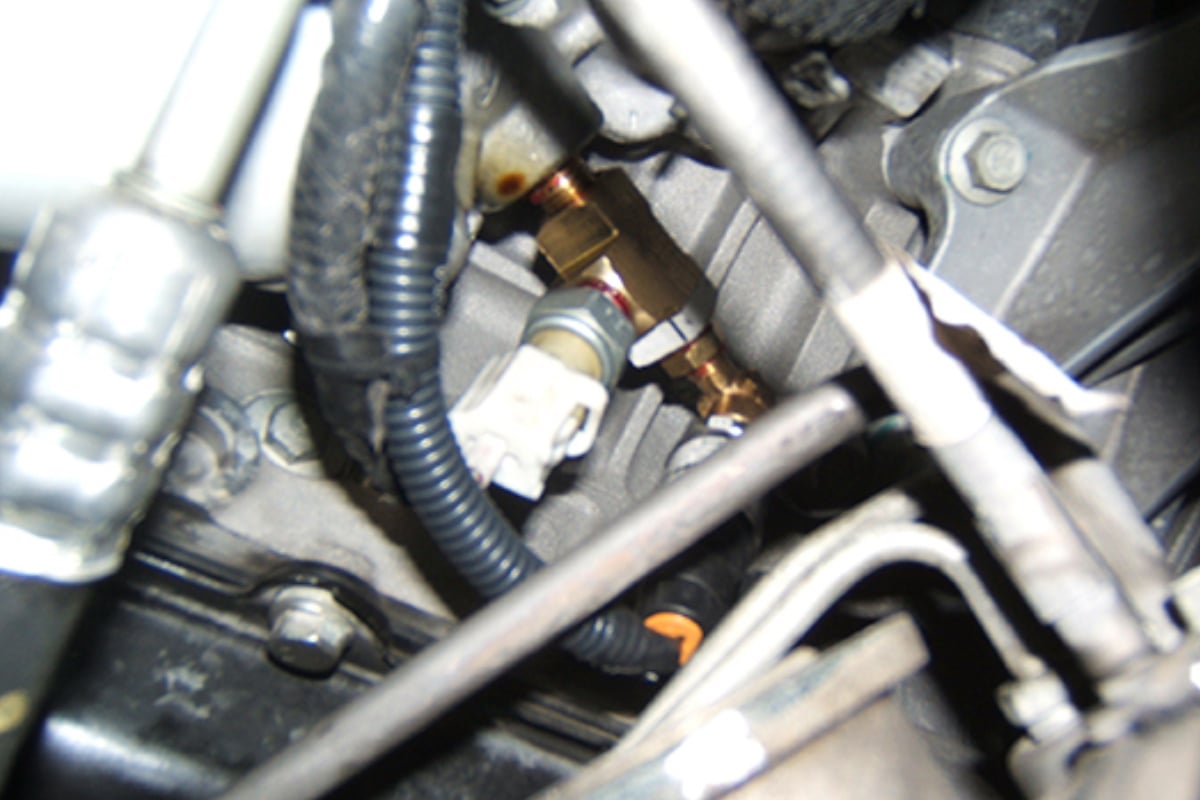

Some engines will have a second, available port above the oil filter, next to the factory oil pressure switch. This will be 1/4″NPT, the appropriate adapter will come supplied with your AutoMeter Oil Pressure gauge.

Some engines will only have one port, which the factory oil pressure switch is already utilizing. If your vehicle has a factory designed gauge to work with this motor (i.e. this is not an engine swap application), then retain the factory switch to keep the “check gauges” indicator from coming on, and use a variety of hardware store-available, brass fittings or performance shop fluid fittings to build a T to house the factory switch, and your new sender.

If there is no factory gauge, you may then eliminate the factory sender/switch, and use a 1/4″NPT to 1/8”NPT adapter bushing to install the AutoMeter sender or mechanical gauge line (this adapter will be included with your AutoMeter Oil Pressure gauge).

When using the above mentioned oil pressure port, you may choose to remote mount the sender to keep too much excess weight and strain off of the T, or just due to room constraints. You may use a stainless braided line kit, such as AutoMeter model number #3227 to accomplish this.

If you cannot, or do not want to use the port near the oil filter, you may also find ports at the rear of either of the cylinder heads. These will either be 1/4″NPT, or 3/8”NPT. In most applications, there is not much room to work with here and will likely require a mirror to locate on a non-swap application. One way to make this port work, is to use a 90 degree adapter into a braided stainless line such as the #3227 mentioned above allowing you to remote mount the sensor in a more convenient or out of the way location.